|

|

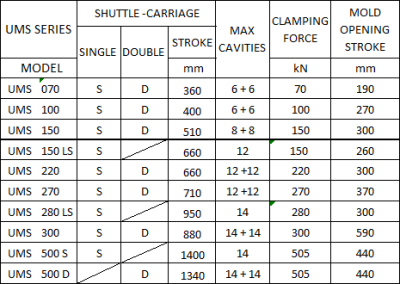

| Process: Continuous extrusion shuttle

The most flexible and widely-used process; the choice worldwide for highest performance specialty applications up to 30 liters. The continuous extrusion shuttle can process virtually all commercial resins enabling you to produce everything from tiny cosmetic containers to largest industrial packaging.Head design is engineered for quick changeover and PWDS (optional) radial parison control to reduce weight, increase strength. Containers are fully trimmed in machine, oriented in stand-up position. Shuttle process features co-extrusion capability for Containers up to 7 layers with in-mould labeling capability. |

|

|

Applications

|

|

English

English Русский

Русский Italiano

Italiano